After effect of global warming has turned to become a reality. This has foster the growth of sustainable construction materials. The trend of sustainable construction encourages the use of green materials, environmentally friendly and energy-saving solutions to minimise the impact on the environment while ensuring functionality, aesthetics, efficiency and also economics.

Green building (sustainable construction) is an inevitable trend in countries around the world. In particular, in Malaysia, the country on the top list of risks of climate change in the next 20-30 years, the development of green buildings needs to be focused and promoted.

To achieve that, construction products need to be oriented and prioritised using green materials, environmentally friendly materials. Green materials are defined as environmentally responsible materials because their effects are considered throughout the life of the material. According to Greenguide's definition, green building products and materials must meet at least one of the following criteria:

- Long service life

- Non-toxic

- Has recycled content

- Saving resources

- Interested in the environment

Following are some green materials that promote sustainability.

Building Materials Derived from Soil

Building materials derived from

soil such as unburnt bricks, clay mixes with corn cobs and lime, clay used to be used for construction purposes since its inception. In order to increase the bearing capacity and durability of the material, it is possible to add grass, straw or other shredded fibers into the composition. Products created from these materials have very high thermal insulation and competitive costs.

Bamboo

Bamboo

Bamboo is a traditional material used in construction works in many localities for thousands of years. Today, along with the trend of green building development, bamboo is indeed a promising construction material for modern buildings in the world. This material has the advantage of durability, weight and rapid regeneration. Bamboo can be used as a framework for buildings, replacing the role of reinforced concrete, especially in areas with abundant bamboo resources, difficult traffic, needs reconstruction after natural disasters.

XPS Insulation Foam

Long time ago, XPS foam was a soundproof and thermal

insulation material used in many civil, industrial and public buildings. Many recent studies on new buildings show that buildings using 15-18cm insulation foam can save electricity consumption of 343-344Wh / m2. This further improve energy saving while enhancing the space for better living.

Lightweight Concrete

Lightweight

Lightweight concrete weighs only half of baked clay bricks, helping to save costs as a foundation. With a high porosity structure, lightweight concrete is well insulated, reducing about 30% of electricity used for air conditioning. In addition, lightweight concrete also has high soundproofing ability, fireproof for about 4 hours. Using lightweight concrete also helps reduce the cost of plastering walls due to the flat concrete surface.

Although the price is higher than conventional bricks by 10-15%, in return, lightweight concrete helps reduce the cost of foundation, plasters, power and also green materials are encouraged to use because of the production process introduces far less emissions than conventional one.

Paint that Does Not Contain VOC

The term VOC (volatile organic compounds) is often used to refer to a mixture of toxic organic substances that fly in the air. VOC exists in most interior paints, exterior, adhesives, cleaning products. VOCs are very volatile and combine with harmless inorganic substances to form new compounds that pollute the environment and do affects human health such as irritation of eyes, nose, headache, dizziness, respiratory diseases, damage to the lungs and nervous system.

Therefore, when choosing wall

paint, you should pay attention to the VOC of paint. Paints with low VOC content are usually more expensive but will be safer. To ensure the health of yourself and your family, you should choose a VOC-free paint (0g/litre) or a VOC content of less than 50g/litre.

Sandbag

Construction technology using soil bags,

sand (earthbag) is highly appreciated by experts because of its low cost, fast completion time and still ensuring solidity and solidity for the project. This trend originates from African countries such as Zimbabwe, South Africa, Mozambique, Madagascar, Namibia.

How to build a sandbag is very simple, sandbags are stacked on top of each other and fixed with steel wire so that they do not slide down. In some countries, such as Colombia, in addition to the main material is sand, people also mix some substances such as lime, cement, clay, and add a layer of live bricks or plaster outside to protect the building from the impact of the environment. This structure can even withstand earthquakes.

Straw Bales

Straw bales are green materials that are widely used in farms because of their high availability and

sound insulation and insulation. In addition, straw bales are also fire resistant because when production, straw is pressed tightly so the air cannot pass. Because the straw is not able to withstand the load, it is only suitable for filling materials between columns or in frames and beams.

Split Stone (Slate)

Split stones are natural stones, split from a large stone block. Thanks to that, the stone has uniform colour and easy to perform tiling. With the ability to withstand high temperatures, load bearing capacity, many colours choice, and natural stone veins, split stones give permanent durability and exquisite beauty. Besides, split stone is produced by unburnt technology, so it has less impact on the environment, lower cost than many other tiling materials.

However, due to the heavy weight and difficult construction, this material is mainly used near mining areas or within economic logistic distance.

Synthetic Roof

Roofing

Roofing sheets made of synthetic materials such as foam insulation or cellulose layers sandwiched between two metal sheets or two plastic sheets are listed in the list of green, environmentally friendly materials. This material is quite light, affordable and has a very good insulation capacity for the structure, thereby reducing power consumption.

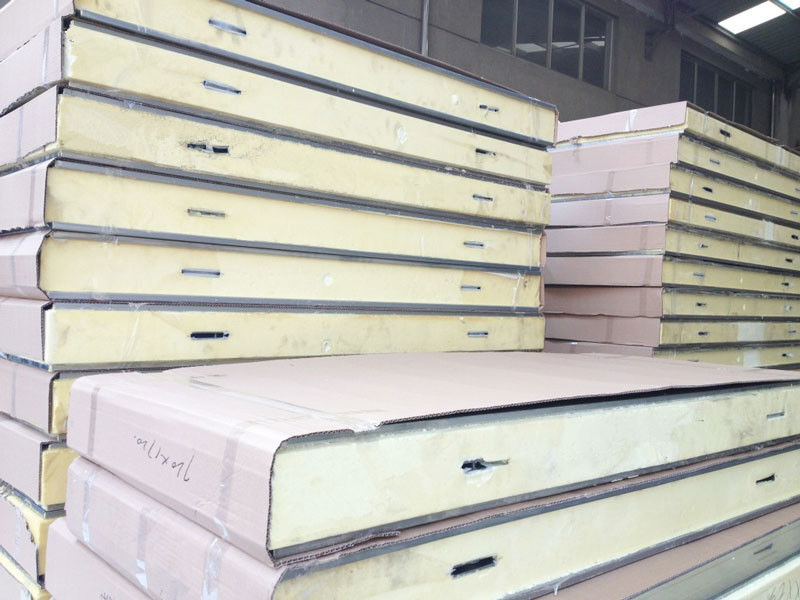

PU Cold Insulation

PU insulation (PolyUrethane) has excellent thermal insulation, moisture resistance, good fire resistance, aging resistance, bearing capacity and high durability. In construction, PU insulation panels are used for making prefabricated houses, prefab houses, hospitals, schools ...

Ecological Roofing Sheet

Ecological corrugated iron is produced from organic fibre cellulose, acrylic and asphalt waterproofing method by laminated method. As a result, roofing sheets are able to withstand harsh weather conditions, are not corroded in salt environments, so they are very suitable for coastal projects. This type of roofing is able to resist heat, sound insulation and insulation to save electricity for air conditioning on days when temperatures rise.

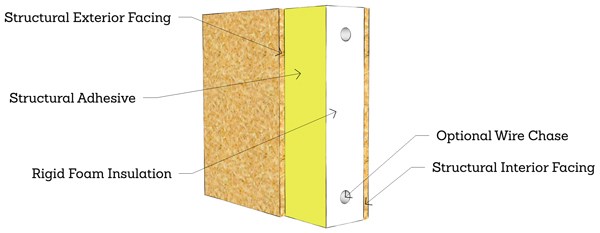

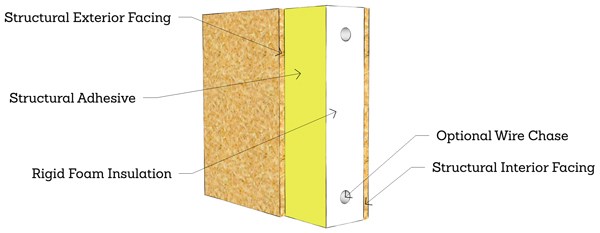

SIPs insulation Panel

The main ingredients that make up SIPs are foam and fibre sheets (OSB). This material loses less material and energy to produce than other structural systems. Not only has good thermal insulation, SIPS insulation panels also help architects achieve LEED Platinum energy certification.

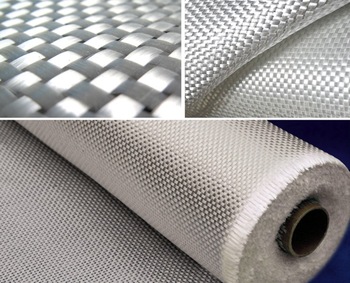

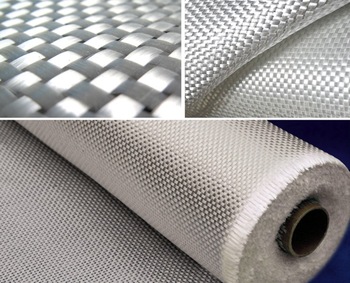

Glass Fibre

Glass fibre

Glass fibre is also used for insulation purposes in the form of glass plates. Although there are some toxic components in glass fibres, due to their super-insulating properties and low cost, it is still considered a green building material.

Natural Fibres

Natural fibres such as cotton and wool are also popular insulation materials for construction works. Cotton or woollen yarn will be pressed into sheets and installed on wooden walls or frames.

The use of recycled construction materials has the effect of reducing the need for new materials, minimising production costs, transportation costs, waste disposal costs and the list goes on. You can make use of recycled materials as suggested below to save costs while still ensuring the quality of the work:

- Plastic: Plastic waste is best recycled when the waste is collected separately, not mixed with other wastes. After cleaned plastic waste can be reused in specially designed products such as cable pipes, PVC windows, roofs or floors.

- Metal: The most reused construction waste is steel. This material is recycled almost completely, allowing repeated recycling.

- Wood: Recycled wood is used from warehouses, old houses, wine barrels, cargo boxes. Excess wood from construction and breakdowns can be reused for other construction projects after cleaning.

- Concrete: Crushed concrete after demolition can be used to make the foundation, levelling the works or making materials to produce unburnt bricks.

- Bricks: Use healthy bricks for retaining walls and auxiliary works; Broken bricks as foundations and paths.

After effect of global warming has turned to become a reality. This has foster the growth of sustainable construction materials. The trend of sustainable construction encourages the use of green materials, environmentally friendly and energy-saving solutions to minimise the impact on the environment while ensuring functionality, aesthetics, efficiency and also economics.

Green building (sustainable construction) is an inevitable trend in countries around the world. In particular, in Malaysia, the country on the top list of risks of climate change in the next 20-30 years, the development of green buildings needs to be focused and promoted.

To achieve that, construction products need to be oriented and prioritised using green materials, environmentally friendly materials. Green materials are defined as environmentally responsible materials because their effects are considered throughout the life of the material. According to Greenguide's definition, green building products and materials must meet at least one of the following criteria:

After effect of global warming has turned to become a reality. This has foster the growth of sustainable construction materials. The trend of sustainable construction encourages the use of green materials, environmentally friendly and energy-saving solutions to minimise the impact on the environment while ensuring functionality, aesthetics, efficiency and also economics.

Green building (sustainable construction) is an inevitable trend in countries around the world. In particular, in Malaysia, the country on the top list of risks of climate change in the next 20-30 years, the development of green buildings needs to be focused and promoted.

To achieve that, construction products need to be oriented and prioritised using green materials, environmentally friendly materials. Green materials are defined as environmentally responsible materials because their effects are considered throughout the life of the material. According to Greenguide's definition, green building products and materials must meet at least one of the following criteria:

Building materials derived from soil such as unburnt bricks, clay mixes with corn cobs and lime, clay used to be used for construction purposes since its inception. In order to increase the bearing capacity and durability of the material, it is possible to add grass, straw or other shredded fibers into the composition. Products created from these materials have very high thermal insulation and competitive costs.

Building materials derived from soil such as unburnt bricks, clay mixes with corn cobs and lime, clay used to be used for construction purposes since its inception. In order to increase the bearing capacity and durability of the material, it is possible to add grass, straw or other shredded fibers into the composition. Products created from these materials have very high thermal insulation and competitive costs.

Bamboo is a traditional material used in construction works in many localities for thousands of years. Today, along with the trend of green building development, bamboo is indeed a promising construction material for modern buildings in the world. This material has the advantage of durability, weight and rapid regeneration. Bamboo can be used as a framework for buildings, replacing the role of reinforced concrete, especially in areas with abundant bamboo resources, difficult traffic, needs reconstruction after natural disasters.

Bamboo is a traditional material used in construction works in many localities for thousands of years. Today, along with the trend of green building development, bamboo is indeed a promising construction material for modern buildings in the world. This material has the advantage of durability, weight and rapid regeneration. Bamboo can be used as a framework for buildings, replacing the role of reinforced concrete, especially in areas with abundant bamboo resources, difficult traffic, needs reconstruction after natural disasters.

Long time ago, XPS foam was a soundproof and thermal insulation material used in many civil, industrial and public buildings. Many recent studies on new buildings show that buildings using 15-18cm insulation foam can save electricity consumption of 343-344Wh / m2. This further improve energy saving while enhancing the space for better living.

Long time ago, XPS foam was a soundproof and thermal insulation material used in many civil, industrial and public buildings. Many recent studies on new buildings show that buildings using 15-18cm insulation foam can save electricity consumption of 343-344Wh / m2. This further improve energy saving while enhancing the space for better living.

Lightweight concrete weighs only half of baked clay bricks, helping to save costs as a foundation. With a high porosity structure, lightweight concrete is well insulated, reducing about 30% of electricity used for air conditioning. In addition, lightweight concrete also has high soundproofing ability, fireproof for about 4 hours. Using lightweight concrete also helps reduce the cost of plastering walls due to the flat concrete surface.

Although the price is higher than conventional bricks by 10-15%, in return, lightweight concrete helps reduce the cost of foundation, plasters, power and also green materials are encouraged to use because of the production process introduces far less emissions than conventional one.

Lightweight concrete weighs only half of baked clay bricks, helping to save costs as a foundation. With a high porosity structure, lightweight concrete is well insulated, reducing about 30% of electricity used for air conditioning. In addition, lightweight concrete also has high soundproofing ability, fireproof for about 4 hours. Using lightweight concrete also helps reduce the cost of plastering walls due to the flat concrete surface.

Although the price is higher than conventional bricks by 10-15%, in return, lightweight concrete helps reduce the cost of foundation, plasters, power and also green materials are encouraged to use because of the production process introduces far less emissions than conventional one.

The term VOC (volatile organic compounds) is often used to refer to a mixture of toxic organic substances that fly in the air. VOC exists in most interior paints, exterior, adhesives, cleaning products. VOCs are very volatile and combine with harmless inorganic substances to form new compounds that pollute the environment and do affects human health such as irritation of eyes, nose, headache, dizziness, respiratory diseases, damage to the lungs and nervous system.

Therefore, when choosing wall paint, you should pay attention to the VOC of paint. Paints with low VOC content are usually more expensive but will be safer. To ensure the health of yourself and your family, you should choose a VOC-free paint (0g/litre) or a VOC content of less than 50g/litre.

The term VOC (volatile organic compounds) is often used to refer to a mixture of toxic organic substances that fly in the air. VOC exists in most interior paints, exterior, adhesives, cleaning products. VOCs are very volatile and combine with harmless inorganic substances to form new compounds that pollute the environment and do affects human health such as irritation of eyes, nose, headache, dizziness, respiratory diseases, damage to the lungs and nervous system.

Therefore, when choosing wall paint, you should pay attention to the VOC of paint. Paints with low VOC content are usually more expensive but will be safer. To ensure the health of yourself and your family, you should choose a VOC-free paint (0g/litre) or a VOC content of less than 50g/litre.

Construction technology using soil bags, sand (earthbag) is highly appreciated by experts because of its low cost, fast completion time and still ensuring solidity and solidity for the project. This trend originates from African countries such as Zimbabwe, South Africa, Mozambique, Madagascar, Namibia.

How to build a sandbag is very simple, sandbags are stacked on top of each other and fixed with steel wire so that they do not slide down. In some countries, such as Colombia, in addition to the main material is sand, people also mix some substances such as lime, cement, clay, and add a layer of live bricks or plaster outside to protect the building from the impact of the environment. This structure can even withstand earthquakes.

Construction technology using soil bags, sand (earthbag) is highly appreciated by experts because of its low cost, fast completion time and still ensuring solidity and solidity for the project. This trend originates from African countries such as Zimbabwe, South Africa, Mozambique, Madagascar, Namibia.

How to build a sandbag is very simple, sandbags are stacked on top of each other and fixed with steel wire so that they do not slide down. In some countries, such as Colombia, in addition to the main material is sand, people also mix some substances such as lime, cement, clay, and add a layer of live bricks or plaster outside to protect the building from the impact of the environment. This structure can even withstand earthquakes.

Straw bales are green materials that are widely used in farms because of their high availability and sound insulation and insulation. In addition, straw bales are also fire resistant because when production, straw is pressed tightly so the air cannot pass. Because the straw is not able to withstand the load, it is only suitable for filling materials between columns or in frames and beams.

Straw bales are green materials that are widely used in farms because of their high availability and sound insulation and insulation. In addition, straw bales are also fire resistant because when production, straw is pressed tightly so the air cannot pass. Because the straw is not able to withstand the load, it is only suitable for filling materials between columns or in frames and beams.

Split stones are natural stones, split from a large stone block. Thanks to that, the stone has uniform colour and easy to perform tiling. With the ability to withstand high temperatures, load bearing capacity, many colours choice, and natural stone veins, split stones give permanent durability and exquisite beauty. Besides, split stone is produced by unburnt technology, so it has less impact on the environment, lower cost than many other tiling materials.

However, due to the heavy weight and difficult construction, this material is mainly used near mining areas or within economic logistic distance.

Split stones are natural stones, split from a large stone block. Thanks to that, the stone has uniform colour and easy to perform tiling. With the ability to withstand high temperatures, load bearing capacity, many colours choice, and natural stone veins, split stones give permanent durability and exquisite beauty. Besides, split stone is produced by unburnt technology, so it has less impact on the environment, lower cost than many other tiling materials.

However, due to the heavy weight and difficult construction, this material is mainly used near mining areas or within economic logistic distance.

Roofing sheets made of synthetic materials such as foam insulation or cellulose layers sandwiched between two metal sheets or two plastic sheets are listed in the list of green, environmentally friendly materials. This material is quite light, affordable and has a very good insulation capacity for the structure, thereby reducing power consumption.

Roofing sheets made of synthetic materials such as foam insulation or cellulose layers sandwiched between two metal sheets or two plastic sheets are listed in the list of green, environmentally friendly materials. This material is quite light, affordable and has a very good insulation capacity for the structure, thereby reducing power consumption.

PU insulation (PolyUrethane) has excellent thermal insulation, moisture resistance, good fire resistance, aging resistance, bearing capacity and high durability. In construction, PU insulation panels are used for making prefabricated houses, prefab houses, hospitals, schools ...

PU insulation (PolyUrethane) has excellent thermal insulation, moisture resistance, good fire resistance, aging resistance, bearing capacity and high durability. In construction, PU insulation panels are used for making prefabricated houses, prefab houses, hospitals, schools ...

Ecological corrugated iron is produced from organic fibre cellulose, acrylic and asphalt waterproofing method by laminated method. As a result, roofing sheets are able to withstand harsh weather conditions, are not corroded in salt environments, so they are very suitable for coastal projects. This type of roofing is able to resist heat, sound insulation and insulation to save electricity for air conditioning on days when temperatures rise.

Ecological corrugated iron is produced from organic fibre cellulose, acrylic and asphalt waterproofing method by laminated method. As a result, roofing sheets are able to withstand harsh weather conditions, are not corroded in salt environments, so they are very suitable for coastal projects. This type of roofing is able to resist heat, sound insulation and insulation to save electricity for air conditioning on days when temperatures rise.

The main ingredients that make up SIPs are foam and fibre sheets (OSB). This material loses less material and energy to produce than other structural systems. Not only has good thermal insulation, SIPS insulation panels also help architects achieve LEED Platinum energy certification.

The main ingredients that make up SIPs are foam and fibre sheets (OSB). This material loses less material and energy to produce than other structural systems. Not only has good thermal insulation, SIPS insulation panels also help architects achieve LEED Platinum energy certification.

Glass fibre is also used for insulation purposes in the form of glass plates. Although there are some toxic components in glass fibres, due to their super-insulating properties and low cost, it is still considered a green building material.

Glass fibre is also used for insulation purposes in the form of glass plates. Although there are some toxic components in glass fibres, due to their super-insulating properties and low cost, it is still considered a green building material.

Natural fibres such as cotton and wool are also popular insulation materials for construction works. Cotton or woollen yarn will be pressed into sheets and installed on wooden walls or frames.

Natural fibres such as cotton and wool are also popular insulation materials for construction works. Cotton or woollen yarn will be pressed into sheets and installed on wooden walls or frames.

The use of recycled construction materials has the effect of reducing the need for new materials, minimising production costs, transportation costs, waste disposal costs and the list goes on. You can make use of recycled materials as suggested below to save costs while still ensuring the quality of the work:

The use of recycled construction materials has the effect of reducing the need for new materials, minimising production costs, transportation costs, waste disposal costs and the list goes on. You can make use of recycled materials as suggested below to save costs while still ensuring the quality of the work: