Eco Friendly Construction Materials That Are Popular Globally

For many years, the problem of environmental pollution and exhaustion of natural resources. The research and development of environmentally friendly construction materials has been receiving good welcome to many green buildings around the world.

Fast Draining Concrete

Although this is not a new technology, but water-absorbing concrete still holds an important position thanks to its effective anti-flood treatment. While conventional concrete has a waterproof structure, the absorbent concrete is made from the same sized rock particles with cement paste, very little or no sand so they have an open pore structure that can effectively allow water to flow through.

This mechanism allows water flow through the surface and is filtered into the ground. Parking areas that use this “thirsty” concrete will help reduce the need for drainage. Drainage concrete can be applied on all floor structures that need to be treated for drainage and flooding.

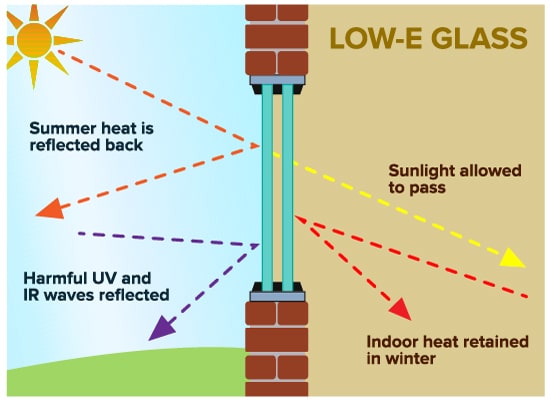

Low Emissivity Glass (Low-E Coating)

Low-E, or low-emissivity, glass is invented to minimise the amount of infrared and ultraviolet light that comes through your glass, without minimising the amount of light that enters your home, office, or any other building structure especially those with many windows or glass structure.

Unburnt Bricks

Unburnt brick is brick that do not use clay materials to produce and do not use fuels such as coal or firewood to burn during the production process.

Unburnt bricks do not affect agricultural land, fuel saving, and most importantly not causing environmental pollution.

Unburnt bricks bring following practical advantages:

- soundproofing is twice as good as terracotta bricks,

- suitable for soundproofing rooms;

- Super-light,

- super-heat-resistant,

- heat-resistant ability helps the construction reduce the load capacity of the foundation structure,

- fast construction progress,

- low water absorption,

- less cement absorption,

- easy cutting.

Environmental Friendly Unburnt Tile

With introduction of advance production technology, there have appeared many types of tiles to build eco-friendly buildings without going through the burning stage such as traditional tile, including methods of moulding and pressing cement to make tiles.

The colour, or hot pressing method of rice husk and plastic blends can create tiles that weigh only one quarter of the regular tile. In addition, clay tiles made of natural clay and bricks are easily recycled into new tile sheets when the cycle is over or broken.

These environmental friendly unburnt tiles have brought a new option for green lover in building or renovating their home, office or other building structure.

Concrete Produced from Ash

Concrete is the most popular and most widely used construction material. This has made it one of the major agents causing global warming.

Emissions generated from concrete production are estimated to account for 5-10% of greenhouse gas emissions. The process of calcining limestone, clay and some additives at 1450 degrees to create cement has caused limestone links to be destroyed, producing greenhouse gases.

The concrete industry aims to use industrial by-products such as ash and blast furnace slag as an alternative to concrete with only cement and padding materials to both reduce:

- the amount of cement needed to improve strength and durability of concrete,

- CO2 reduction from 15% to 40%.

Finally, when a concrete structure has completed its first purpose, concrete can be crushed to be a filler for new concrete or as a base material for roads and sidewalks.